Introduction

Global supply chain technology has been impacted as a result of the recent pandemic and war scenarios that have created an imbalance between supply and demand for commodities.

Nearly every area is being clearly transformed by digitalization, but the manufacturing and logistics sectors may be where the notion is having the biggest effects.

Companies are utilising a sophisticated set of technologies in the supply chain to expand their business innovation as a result of increasing globalisation, increased product complexity, and constantly shifting client needs.

Global supply chain technology has been impacted as a result of the recent pandemic and war scenarios that have created an imbalance between supply and demand for commodities. The likelihood of lockdowns or another conflict cannot be ignored, but these dreadful circumstances have also increased the necessity for businesses to use tech-led supply chain management systems to meet the problems.

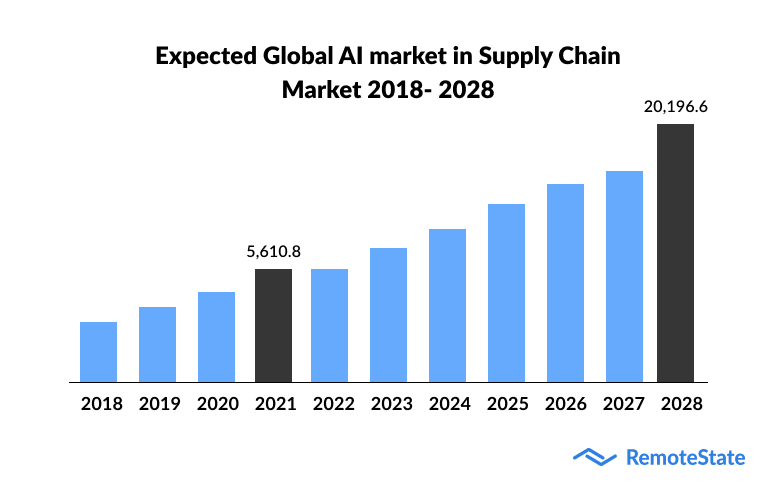

It is not unexpected to see businesses investing in sophisticated supply chain optimization solutions as they become more wary of the future. By 2023, 50% of global eCommerce enterprises will, according to Gartner, invest in AI, a real-time supply chain, and cutting-edge analytical solutions.

They wish to spend in order to address the troubling problems of the disruption of the global supply chain.

Problems in the current supply chain technology

Even though the supply chain's adoption of digitization was expedited by the current economic climate, there were a number of shortcomings that came to light. A revelation that made information technology's crucial functions in supply chain management necessary.

1. Labor and Material shortage

Multiple layoffs occurred in 2020–21, and a global market disruption was caused by quarantine. In addition to having trouble delegating, leaders are increasingly having trouble filling important roles in supply chain operations and procurement.

The Institute of Supply Chain Management research claims that every essential resource—both human and material—is expensive or hard to come by, creating complications and shortages in the sector. a scarcity that necessitates supply chain management using cutting-edge technology.

2. Rising freight prices

Intermodal transportation experienced enormous growth in 2021, and spot prices also doubled; for example, the price changes for reefer (+25%), van (+18%), and flatbed (+27%) vehicles. Additionally, the cost of shipping goods by air and sea has increased dramatically, making it difficult for businesses to operate at full capacity. As a result, companies have made investments in cutting-edge supply chain and logistics technologies in an effort to identify the most economical solutions.

3. Port overcrowding

Long lines have formed for ships entering ports all over the world in the last two years. For the purpose of offloading cargo from China last year, in October 2021, more than 50 container ships gathered just outside of Los Angeles and Long Beach. Gridlocks like these delay ships while they search for goods, especially at the foreign port. Such bottlenecks cause both import and export activities to take longer, which disturbs the domestic supply chains.

Although port congestion is not a new problem, the National Customers Brokers & Forwarders Association of America (NCBFAA) forecasts that supply chain disruptions and lengthy wait times may occur in 2022. And as a result, supply chain management will increasingly leverage technology.

4. Demand forecasting limitations

While the supplier network data was impacted by the global shutdown in 2020, initiatives to digitalize were suddenly adopted in 2021. As a result, there were no benchmarks for supply chain executives to operate around, which opened up the possibility of implementing global supply chain technology.

Addressing them nevertheless remains a challenge due to the extraordinary demand. To address this, the leaders are using current data to forecast the upcoming year and establish standards for everything from inventory to pricing and budget.

Therefore, even after the digitalization prompted by COVID, these remain the top difficulties facing the supply chain industry. Utilizing a variety of modern technologies in the supply chain will help solve these problems. Let's investigate them next.

The group of information technologies that has the most impact on supply chain management

The supply chain is undergoing rapid technological change. What was once limited to paperwork and spreadsheets is now being improved upon with the use of cutting-edge technology like artificial intelligence (AI), the internet of things (IoT), blockchain, robotic process automation (RPA), etc. Let's go to the list of technologies and how they are assisting in addressing supply chain management's difficulties.

IOT

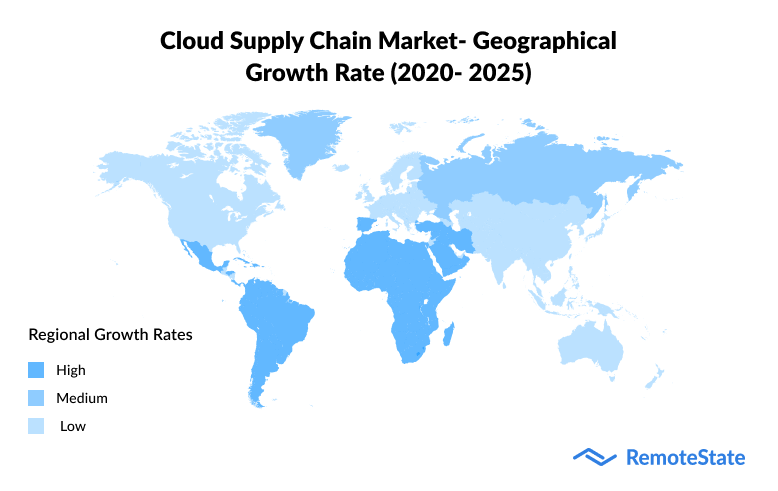

The supply chain sector is recognising a sizable opportunity in the global supply chain technology, particularly in censored and connected items like shipping containers, commodities, and warehousing stations, as IDC predicts double-digit yearly increase in worldwide IoT spending in 2022.

Manufacturers and transportation businesses are predicted to invest in IoT implementations, particularly to support manufacturing operations, production asset management, and fleet management.

Businesses will be considering IoT and AI in supply chain management for a variety of use cases including enabling location tracking, monitoring the weather, traffic patterns, etc. With the help of this information, the suppliers, for instance, might divert the cargo to a nearby distribution facility or send out a repair staff to handle problems as they arise.

Blockchain

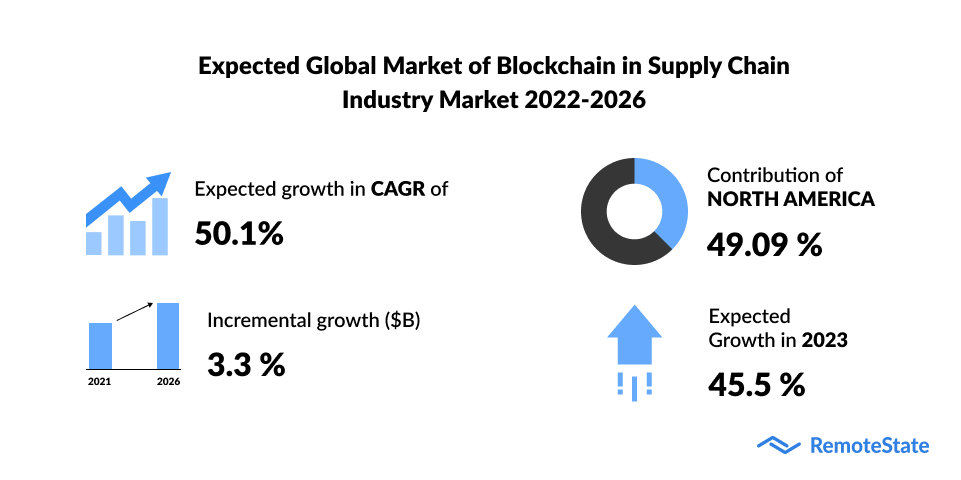

Without mentioning blockchain, it will be hard to discuss the disruption of the global supply chain. The platform relies on an immutable set of transactions, making it ideal for tracing the provenance of products and building confidence in supplier data and supply chain operations.

Due to its immutability, blockchain in supply chain management creates an audit trail, which is significantly more effective than conventional tracking methods like email or bookkeeping.

As a result, allowing track-and-trace use cases that assist enterprises in examining the chain of custody of items constitutes the largest blockchain in supply chain example. As a result, it becomes easier to spot fake goods and fraud cases, identify the riskiest suppliers, make sure that legal criteria are followed, and increase the transparency around the origin and flow of commodities. Due to all of this, blockchain technology in the supply chain is one of the industry's most lucrative investments.

AI

Each modern supply chain network comes with a vast array of data that can be used to gain new understanding of the world's otherwise complex supply chain technology.

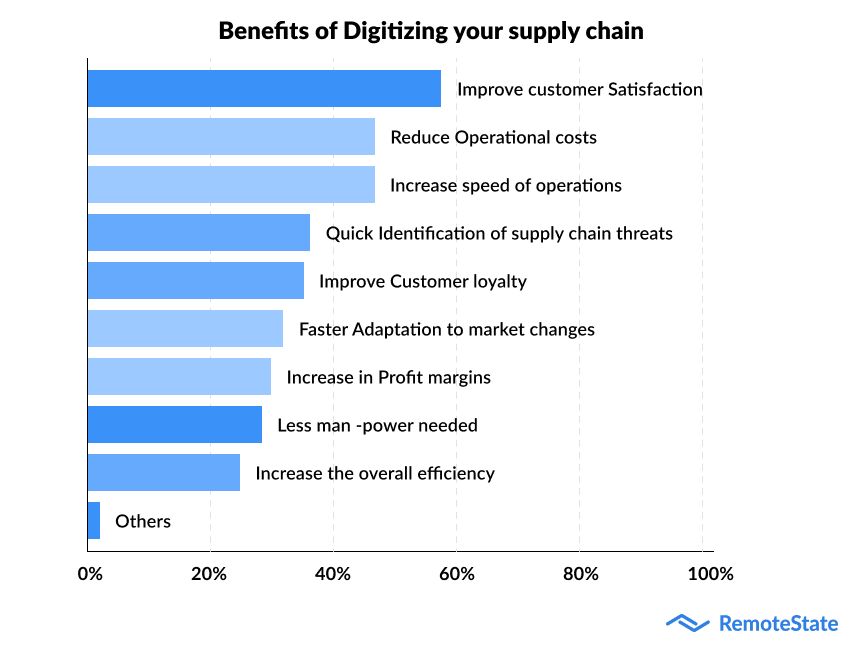

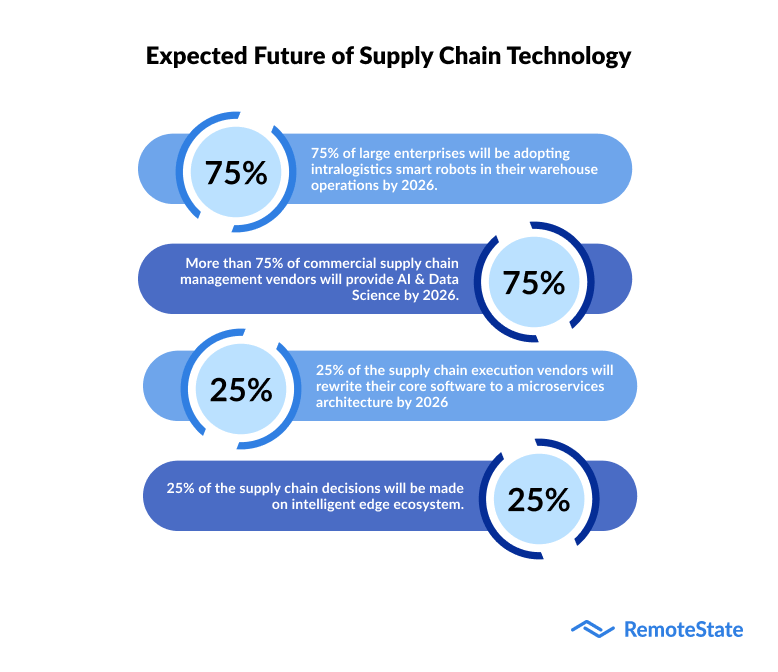

Companies are able to automate warehouse operations, improve delivery times, manage inventory proactively, optimise sourcing relationships, and create new experiences that improve user satisfaction and boost sales by combining technology in supply chain management and logistics such as AI, predictive analytics, and machine learning.

Businesses are able to analyse massive data sets and acquire insights on a microscopic level using predictive methodologies and artificial intelligence algorithms in supply chains, all with essentially no human participation. This is among the main justifications for why companies are turning to AI as an essential supply chain and logistics technology.

Robots and automation

The technology used in supply chains has always been heavily reliant on robots. It has been employed by the sector to conduct order fulfillment and move materials in the warehouse. However, as AI develops the technology of the robots, they will become capable of taking on manual, human-driven jobs like order picking and packing and automated supply chain technology.

Cloud computing

Businesses are using AI-powered clouds to turn the enormous volumes of data that the supply chain generates each year into insights. When combined with artificial intelligence, cloud computing has the potential to change supply chain operations and increase its capacity for complexity management.

The impact of technology in supply chain management can be best seen in bringing the Cloud and AI systems together, which makes use of the market indicators and past trends to achieve the following processes:

-

the process of automating being powered

-

improving the selection process for suppliers

-

obtaining current information about shipments

-

examining the performance of the carrier

-

The process of onboarding suppliers will be simplified.

-

recognizing operational problems and patterns

-

Increasing client service

Businesses are now able to foresee demand, make the supply chain process transparent, and shorten delivery deadlines thanks to the inclusion of these technologies to the supply chain industry. a situation that has sparked a number of trends showing how technology has impacted supply chain management.

The supply chain's new technology trends

It is impossible to ignore disruptions in the supply chain. It is amazing to see how the industry has changed between the COVID era and today. We are only a few steps away from the entire global digitalization of supply chain thanks to technologies like artificial intelligence in the supply chain, IoT, cloud computing, robotics, and blockchain in supply chain management making their entry more prominent in the field.

These supply chain disruption patterns are just the tip of the iceberg in terms of what the industry will see over the next few years. We will soon enter a period where enterprises, especially those in manufacturing and logistics, will become more efficient as a result of the increasing adoption of next-generation technology in the field.

It becomes essential to invest in the appropriate set of technologies for the goods-driven business; supply chain app experts like Remotestate may assist with this. We have a wealth of experience in supply chain engineering and consulting for digital transformation.

We specialize in using next-generation technologies like AI, blockchain, IoT, and robotic process automation to alter supply chains across a variety of industries. Our team of development specialists is well-versed in how to do this.

Recently, we developed intelligent supply chain software in collaboration with a major manufacturer of heavy construction and mining equipment to enable them better respond to the demands of their customers. Additionally, the process automation facility we implemented allowed their personnel to focus on more important tasks rather than tedious ones, which increased their productivity and efficiency.

Contact us right now to start your supply chain adventure now that you know how technology helps in the supply chain.

Publication Date

2022-12-14

Category

Logistics

Author Name

Sajal Nehra