Introduction

Measurements of current goods, raw materials, or property are inventory analytics. Its goal is to monitor stock levels, be it current inventory that impacts business processes, or highlight areas needing improvement.

Analytics in Inventory Management

Measurements of current goods, raw materials, or property are inventory analytics. Its goal is to monitor stock levels, be it current inventory that impacts business processes, or highlight areas needing improvement.

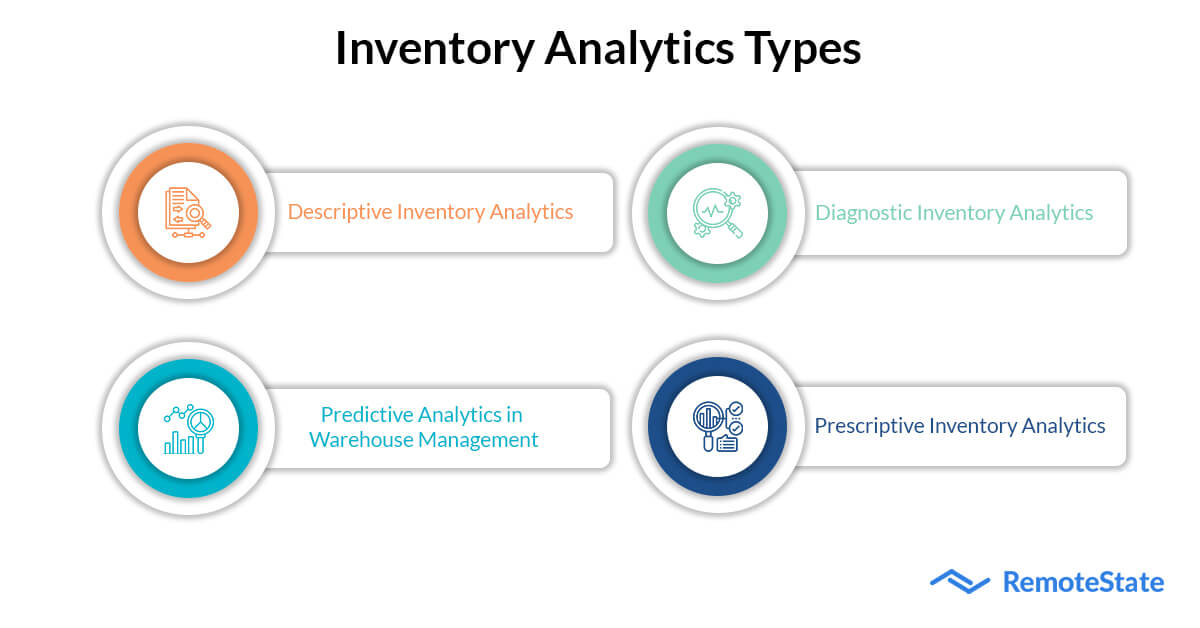

Inventory Analytics Types:

There are many different types of inventory analytics on the value of the data it provides. Descriptive, diagnostic, predictive, and prescriptive inventory analytics offer value in a variety of ways.

-

Descriptive inventory analytics: Descriptive inventory analytics tell you what is happening. The majority of inventory management solutions already have preconfigured descriptive statistics making these insights the simplest to access. Metrics like the number of things on hand and the cost per unit are frequently found on dashboards and are included in this analytics.

-

Diagnostic inventory analytics: Just analyzing is not enough, root cause analysis is important. Diagnostic inventory analytics tells you the root cause i.e. the fundamental of why something is working out for the best for a particular department of an organization. This way one can apply the same fundamental to the other departments.

-

Predictive analytics in Warehouse Management: As the name suggests, predictive analytics forecasts the future which is likely to happen. It tells the inventory manager by looking at the seasonal trends of the past and what is expected to happen in the future. Inventory forecasting can be done to make adjustments to meet the needs of the future. The UK’s plan to leave EU predicted early warning of a potential supply chain interruption using this technology.

-

Prescriptive inventory analytics: This is a very advanced style of analytical tool. It forecasts the quantities of an item necessary to fill most of the orders in a three-day period. The tool tells you what to do next so that you don't miss out on any of the orders in the near future.

Inventory Analytics Dashboard

Nobody likes loads of excel sheets to look at when they want to analyze data. Inventory dashboards gather data, compile them and present them in a single and simple dashboard format. It is a visual way that includes out-of-stock, time-to-sell stock, inventory, and volume items in a single screen making it easier to understand. Some of the tabs include:

-

Categorization of Inventory

-

Today’ Volume

-

Out-of-stock items

-

Average time to sell in days |

How inventory analytics can help your business

Companies can save money by establishing best practices for analytics, hiring the right people, and implementing enabling technologies early on. Top practices consist of:

-

Centralizing data: Centralizing data has the advantage that when it resides in single system as opposed to disconnected silos, all stakeholders can communicate and collaborate easily.

-

Inventory Classification: Inventory classification can help sort out your data for easy monitoring and management. Classification may be XYZ, where X items are the most important as they sell out more and give maximum profits. Then comes item Y which provide less profit, then comes item Z, which contributes to the least amount of profit. Then dive into further specifics, including clothing, gadgets, home items, and outdoor. You can see data based on a variety of criteria thanks to classification.

Get accurate information across systems: Inventory Analytics can help centralize data associated with multiple moving parts of the supply chain. This will ensure the company decisions are accurate and complete.

-

Use real-time dashboards: Only Real-time data is valuable, what's the use of the data if it is not current? Management always wants to know current inventory levels and perform forecasting correctly. Staff and leadership may immediately evaluate status and productivity thanks to technological solutions that offer real-time, practical measurements in a centralized view.

How Predictive Analytics Are Used in Inventory Management

Predicting inventory management in advance helps a company succeed a company a fast-paced market. Predictive forecasting using analytics in inventory management based on holidays, weather, and economic trends, for example, reduces excess inventory and stock levels.

Companies that manually manage inventory or who rely on descriptive analytics are unable to control their inventory and utilize up to the maximum output. When a company uses predictive analytics, it forecasts future trends and patterns, either reduces or minimizes out-of-stock situations and forecasts profitability or forecasts demands more accurately.

Predictive inventory analytics also enable the inventory manager to:

-

Establish stock priorities based on demand and profitability

-

Establish precise procurement levels for product manufacturers and suppliers

-

Minimize supply chain disruptions

-

Forecast sales and demand

-

Optimize transportation routes and make necessary modifications

-

Reduce waste when the solution detects a pattern in damaged items from a supplier; and enables the marketing team to customize suggestive selling based on buyer trends, excess stock, or most popular items.

Inventory Management through Inventory Analytics

Common inventory challenges can be solved using big data coupled with the ability to measure and analyze predictable demand. Data-driven decisions with accurate forecasting prevent inventory overselling, shrinkage, shortages, and overselling-preventing costs directly impacting profitability.

Today’s consumers want immediate delight and expect to have almost everything they desire within hours at their doorstep. In such a highly competitive atmosphere, retailers cannot afford to have out-of-stock situations or delayed deliveries. If a vendor states 48 hours of deliveries, then the consumer expects the item within 48 hours or less. If the vendor does not deliver the item within that time frame, chances are the buyer may switch to another seller next time. It is critical that you meet the customer's demand for the exact product when they want and within the time frame they want.

It's difficult to meet the needs of today's consumers. It needs a large amount of data, kept in a central warehouse and linked to a contemporary inventory management system. Data on customers, products, orders, suppliers, and purchases are required for informed decision-making. Inventory management is optimized by using a prediction-based model that incorporates historical big data, increasing customer happiness and profitability.

How might Remotestate support Inventory Analytics in the Logistics industry?

One of the fastest-growing providers of Logistics software, Remotestate offers custom made Inventory Analytics solutions that may easily automate your Logistics business operations. Our staff works tirelessly and enthusiastically to meet and exceed your expectations at every stage, from ideation through implementation.

Contact our specialists right away to get the ideal Inventory Analytics in Logistics solution for your company!

Publication Date

2023-02-03

Category

Logistics

Author Name

Sajal Nehra