Introduction

With enhanced data reporting, business intelligence (BI) is believed to enable quicker and simpler decision-making.

With enhanced data reporting, business intelligence (BI) is believed to enable quicker and simpler decision-making.

Today, more than 50% of firms already believe that BI is necessary to thrive in the current technology environment. According to Market Watch's most recent analysis, the BI market will have a spectacular increase in CAGR in terms of revenue.

According to a different report, the development of business intelligence has been fueled by several causes, including growing analytics investments, rising dashboard demand, growing emphasis on digital transformation, rising cloud adoption, and IoT in supply chains and other industries.

When it comes to the adoption of business intelligence in a particular industry, the expansion of supply chains and on-demand logistics has been a major factor. The use of BI solutions has been greatly influenced by the logistics industry. According to industry experts, to maintain competitiveness in the supply chain management industry, you must identify any potential weaknesses inside your organization and devise strategies to address them. You may discover potential dangers affecting your business and take prompt corrective action with the use of technological tools like artificial intelligence, analytics, and business intelligence.

Simply put, you can receive automatic recommendations, analyze the production process using the transactions, and gain insights based on real-time actionable data.

Now that we have arrived at our topic, why are supply chains and operations embracing business intelligence solutions so quickly?

The supply chain's digital transformation, where BI excels in a variety of sectors, is probably to blame for the rising use.

Business intelligence's effects on the supply chain process

The volume of data that moves throughout the supply chain industry is limitless. BI basically entails turning this ocean of data into knowledge for useful business applications. What kind of supply chain data is driven by business intelligence, you could ask?

Business intelligence plays a significant role in the management of data including maintenance costs, shipping costs, KPIs (key performance indicators) on carriers and suppliers, strategic planning, and trend research.

Additionally, this data must be further broken down to provide the necessary details for research and analytics. The final numbers show you how the business should behave in light of its performance and business goals.

To assist you monitor the development, BI supply chain tools like dashboards and scoreboards also give you a full summary of a company's performance (daily, weekly, and monthly). This demonstrates the importance of business intelligence throughout the supply chain.

Four supply chain segments that use the BI model

In terms of how the business intelligence model affects the supply chain process, four key sectors are significantly impacted. Let's quickly scan each of them.

Distribution-focused business intelligence

The main responsibility of BI is to make sure that the product gets to the client quickly. The transient services that follow local delivery are tracked with the aid of business intelligence software. The concerned management can move quickly to address the issue if deliveries take longer than anticipated.

BI is a master at tracking products, but it's also adept at tracking extraneous costs like petrol, delivery estimation, and other business expenses. Simply said, you receive every minute detail to capture to increase earnings.

Demand planning with business intelligence

Demand planning is another component of supply chain management that heavily relies on business intelligence. Demand management is essential since it informs you of the volume of output needed for your company to turn a profit. Solutions for business intelligence assist in demand forecasting. The tools predict the amount of time and resources required to meet customer expectations by combining historical data, market segmentation, and sales pipeline data.

Demand planning is a crucial component of the supply chain since it directly affects a company's profit margins if it under or overproduces.

Business intelligence for the Internet of Things machinery

Supply networks have significantly adjusted to the shift towards smart industries. IoT in manufacturing refers to the idea of connecting numerous pieces of equipment and gadgets to the Internet of Things and operating in a data-driven loop. IoT data collection yields information on machine uptime, ensuring the product's consistency. In turn, BI makes use of this information to provide monthly reports outlining areas for improvement.

Additionally, these networked gadgets can notify organizations when routine maintenance is needed. This reduces outages and controls costs.

Business intelligence for managing inventories

Inventory data may be accessed by BI tools, which makes it simple to optimize volume levels for greater profits. The majority of BI inventory solutions monitor sales, purchase totals, and supplier information. You can use all of this data on a single platform to make sure that your company always has the right amount of inventory.

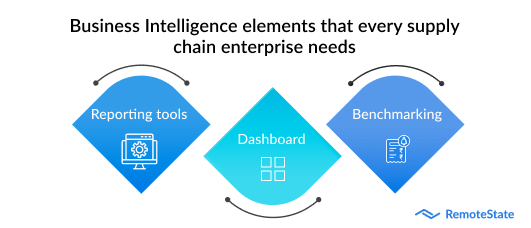

Business Intelligence elements that every supply chain enterprise needs

Here are three crucial BI categories that every supply chain organization must use to boost productivity and efficiency now that we know that business intelligence is all about leveraging data to better plans and decisions.

Reporting tools

Supply chain businesses now rely increasingly on scorecards to aid managers and decision-makers in streamlining workflow. A thorough examination of routine events that can reveal your pain areas is produced with the use of predictive analysis and deep insights into the data. These flaws can also be used to change supply chain management plans.

Dashboards

One of the most impressive features of business intelligence is the real-time visibility of actionable dashboards. It prompts quick responses and provides a short overview of the supply chain cycle. You may easily scroll and navigate with the help of the BI dashboards' adaptable features. You may use dashboard tools like data tables and filters to improve data visualization and get a better overview of your internal operations.

Benchmarking

Any company that uses benchmarking has an advantage in the supply chain market. To improve performance, this includes evaluating your supply chain operation against industry standards. The goal of BI-directed data benchmarks is to enhance business processes and spot expansion prospects.

Key advantages of BI tools for supply chain management

Here are a few of the important features and advantages of business intelligence solutions that enable data sharing within an organization between various functional divisions for consistent decision-making.

-

For analysis, supply chain BI systems assist in drilling down data layers into any format. Charts, spreadsheets, and hyperlinks are just a few of the formats that can be used to track the enterprise's daily operations.

-

Databases can be combined for performance assessment using balanced scorecards as part of BI systems. Additionally, this aids in the creation of essential data visualizations that clarify important information.

-

Integrated reporting and dynamic query creation tools that collect intermediate data and perform analysis for all potential negative outcomes are also provided by BI.

-

With the help of the extra BI tools, businesses may establish a baseline against particular indicators to determine what they should monitor on a daily, weekly, monthly, and annual basis.

-

Customization is also possible with BI, so your dashboard may offer more relevant data to assist you to acquire deeper insights.

Final thoughts!

Integrating business intelligence into your supply chain process is more than just a crucial first step for you if you want to improve it. The goal of BI is to enhance business performance and customer happiness through a comprehensive approach to data collection, processing, and distribution. Connect with us for Business Intelligence solutions if you want us to help your supply chain expand.

Remotestate offers BI services and products that assist businesses in embracing and mastering new technological developments. From BI consulting to developing a complete BI solution to maintaining it, we are at your side.

Publication Date

2023-02-16

Category

Logistics

Author Name

Sajal Nehra