Introduction

Artificial Intelligence (AI) and Machine Learning (ML) have transformed the logistics industry, making it more efficient and effective. AI and ML have become essential tools for optimizing logistics operations, enabling businesses to gain insights into their supply chains, improve decision-making, and enhance their overall performance.

Artificial Intelligence (AI) and Machine Learning (ML) have transformed the logistics industry, making it more efficient and effective. AI and ML have become essential tools for optimizing logistics operations, enabling businesses to gain insights into their supply chains, improve decision-making, and enhance their overall performance.

This blog mainly explores the advantages and disadvantages of implementing AI and ML technologies in logistics operations.

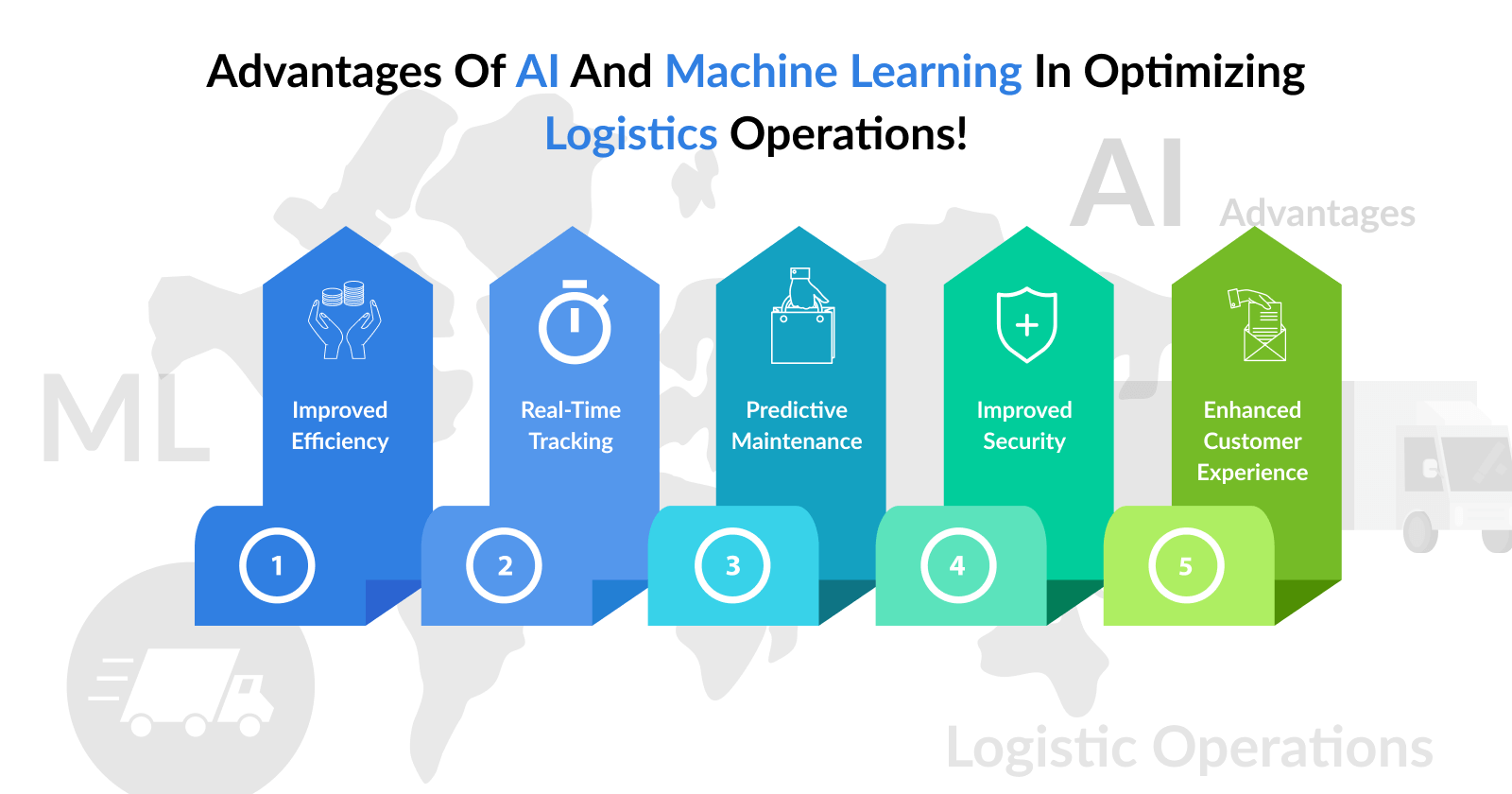

Advantages of AI and Machine Learning in Optimizing Logistics Operations:

Improved Efficiency

AI and ML technologies can analyze data in real-time and optimize logistics operations for maximum efficiency. This reduces the time and costs associated with manual processes, making logistics operations faster and more cost-effective.

Better Decision-making

By processing vast amounts of data, AI and ML algorithms can provide businesses with actionable insights, enabling them to make informed decisions that improve their supply chain performance.

Enhanced Customer Experience

AI and ML technologies can help businesses personalize their logistics operations to meet the specific needs of their customers. By providing faster and more reliable shipping, companies can improve customer satisfaction, which leads to increased sales and loyalty.

Increased Productivity

AI and ML can automate repetitive tasks, freeing up staff to focus on more strategic tasks that require human expertise. This not only increases productivity but also reduces the risk of human error.

Improved Inventory Management

AI and ML technologies can predict demand and optimize inventory levels, reducing the need for excess stock, minimizing waste and reducing costs.

Real-Time Tracking

With the help of AI and ML, logistics companies can track shipments in real-time, enabling them to provide customers with accurate information about delivery times and reducing the risk of lost or delayed shipments.

Predictive Maintenance

AI and ML can help identify potential equipment failures before they occur, enabling logistics companies to perform maintenance proactively, reducing downtime and costs.

Reduced Carbon Footprint

By optimizing logistics operations, AI and ML can reduce fuel consumption and emissions, making logistics operations more sustainable.

Improved Security

AI and ML can help detect and prevent security breaches, protecting goods in transit and reducing the risk of loss or theft.

Improved Supply Chain Visibility

AI and ML can provide businesses with real-time visibility into their supply chains, enabling them to identify bottlenecks, optimize routes, and improve supply chain resilience.

Disadvantages of AI and Machine Learning in Optimizing Logistics Operations:

High Costs

The implementation of AI and ML technologies can be costly, and small logistics companies may not be able to afford them.

Technical Expertise

Implementing AI and ML technologies requires specialized technical expertise that may not be available within the company. This may require hiring external consultants or investing in employee training.

Data Quality

The quality of data used to train AI and ML models is critical. If the data is incomplete, inaccurate, or biased, the algorithms will produce flawed results.

Limited Flexibility

AI and ML models are designed to work within specific parameters, making them less flexible than human decision-making.

Reliance on Technology

The dependence on technology can increase the risk of system failures or cyber attacks, which can disrupt logistics operations.

Ethical Concerns

The use of AI and ML technologies raises ethical concerns, such as privacy, bias, and discrimination. Companies must be mindful of these issues when implementing AI and ML in their logistics operations.

Risk of Job Loss

The automation of repetitive tasks may result in job losses for logistics workers. Companies must consider the social implications of implementing AI and ML technologies in their logistics operations and have a plan in place to retrain or redeploy affected workers.

Integration Challenges

Integrating AI and ML technologies with existing logistics systems can be challenging. It requires significant time and effort to ensure that the technologies work seamlessly with existing systems and that staff are trained to use them effectively.

Lack of Standardization

AI and ML technologies are still evolving, and there is a lack of standardization in the industry. This can make it difficult to choose the right technology for a company's needs and can result in interoperability issues.

Regulatory Compliance

Companies must comply with regulations when implementing AI and ML technologies in their logistics operations. Regulations may vary by jurisdiction, and companies must ensure that they are in compliance with all applicable laws and regulations.

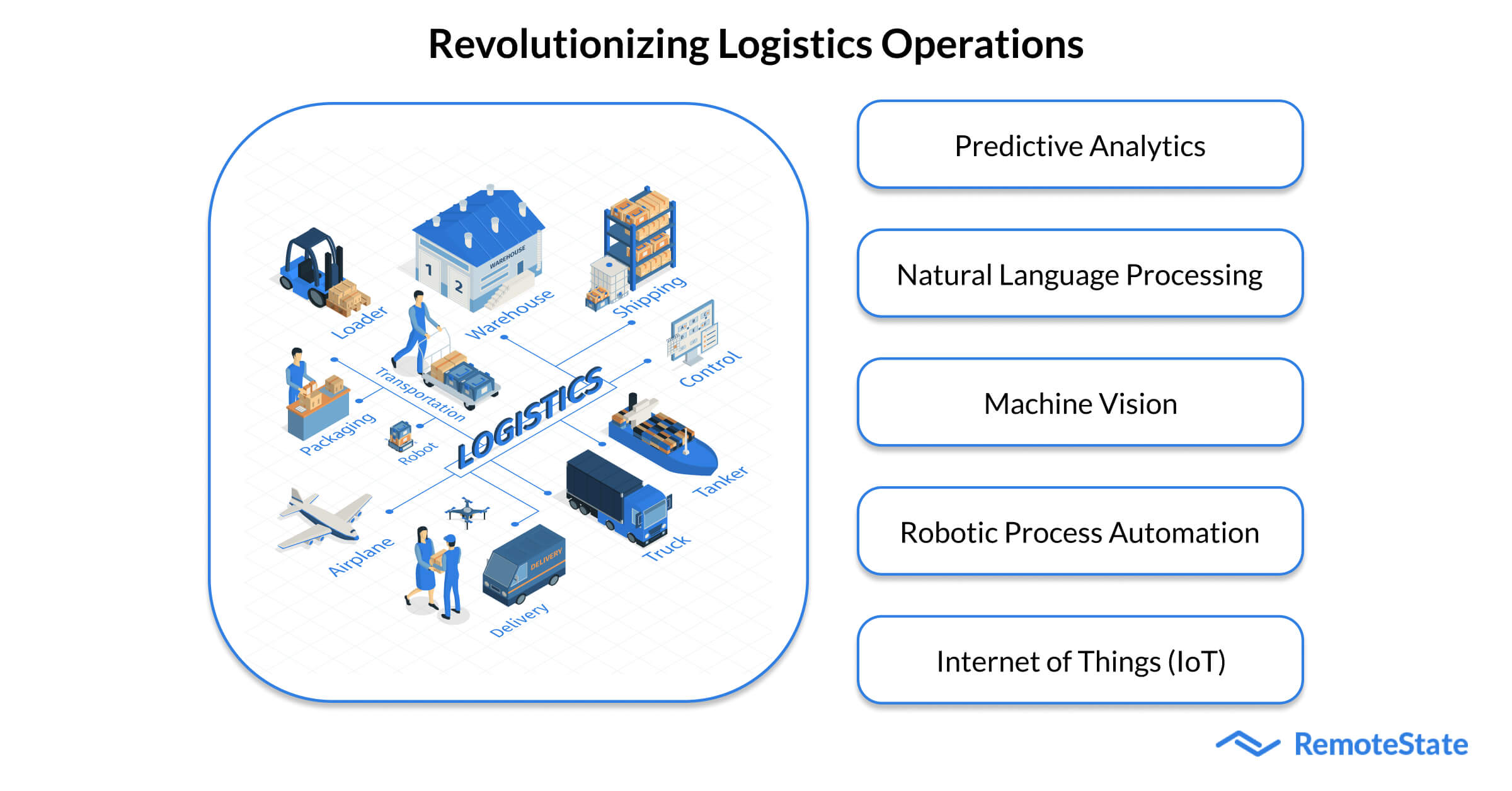

Revolutionizing logistics operations

here are a few examples of how logistics companies can implement AI and ML technologies to optimize their operations:

Predictive Analytics

Logistics companies can use predictive analytics to forecast demand and optimize routes. For example, companies can use predictive analytics to determine the optimal delivery routes based on real-time traffic data and weather patterns.

Natural Language Processing

Companies can use natural language processing to analyze customer feedback and improve their overall customer experience. For example, companies can use chatbots to provide customers with real-time updates on their shipments and address any concerns they may have.

Machine Vision

Logistics companies can use machine vision to automate the process of identifying and sorting packages. For example, companies can use machine vision to read and interpret barcodes, making the sorting process more efficient and accurate.

Robotic Process Automation

Companies can use robotic process automation to automate repetitive and time-consuming tasks such as data entry and invoice processing. For example, companies can use robotic process automation to automate the process of creating shipping labels and tracking shipments.

Internet of Things (IoT)

Companies can use IoT devices such as sensors and RFID tags to track the movement of goods and monitor their condition. For example, companies can use IoT devices to monitor the temperature and humidity of perishable goods during transport to ensure that they arrive in good condition.

By implementing these and other AI and ML technologies, logistics companies can improve their efficiency, reduce costs, and enhance the overall customer experience.

Conclusion

AI and ML technologies have the potential to transform logistics operations, enabling businesses to optimize their supply chains and improve their overall performance. However, implementing these technologies comes with its own set of challenges and risks.

Companies must carefully consider the advantages and disadvantages of implementing AI and ML in their logistics operations and develop a comprehensive plan to ensure a successful implementation. By doing so, logistics companies can take advantage of the benefits of AI and ML technologies and improve their competitiveness in an increasingly complex and competitive global economy.

Optimize your Logistics Operations with Remotestate's AI and ML Solutions!

As a tech company specializing in AI and machine learning, Remotestate can help logistics companies implement these technologies in their operations. Our team of experts can work with logistics companies to assess their needs and develop a customized plan for implementing AI and ML technologies. Some of the ways in which Remotestate can help logistics companies include:

Data Analysis

Remotestate can help logistics companies analyze their data and identify patterns that can help them optimize their operations.

Predictive Analytics

Our team can help logistics companies develop predictive models that can forecast demand and optimize routes.

Natural Language Processing

Remotestate can help logistics companies use natural language processing to analyze customer feedback and improve their overall customer experience.

Machine Vision

Our team can help logistics companies develop machine vision solutions that automate the process of identifying and sorting packages.

Robotic Process Automation

Remotestate can help logistics companies automate repetitive and time-consuming tasks such as data entry and invoice processing.

By working with Remotestate, logistics companies can take advantage of the benefits of AI and ML technologies and improve their competitiveness in an increasingly complex and competitive global economy.

FAQ's

Q: How can AI and ML improve logistics operations?

A: AI and ML can improve logistics operations by optimizing routes, reducing costs, improving inventory management, providing real-time tracking, and enhancing the overall customer experience.

Q: What are the disadvantages of implementing AI and ML in logistics operations?

A: The disadvantages of implementing AI and ML in logistics operations include high costs, technical expertise requirements, data quality issues, limited flexibility, reliance on technology, ethical concerns, risk of job loss, integration challenges, lack of standardization, and regulatory compliance.

Q: What types of AI and ML technologies are commonly used in logistics operations?

A: Commonly used AI and ML technologies in logistics operations include predictive analytics, natural language processing, machine vision, and robotic process automation.

Q: How can logistics companies prepare for the implementation of AI and ML technologies?

A: Logistics companies can prepare for the implementation of AI and ML technologies by assessing their needs, selecting the right technology, investing in employee training, ensuring data quality, and developing a plan for dealing with social and ethical issues.

Publication Date

2023-02-23

Category

Logistics

Author Name

Sajal Nehra